3D Print Cases

This guide explains how to 3D print, prepare, and assemble the official Lichee-Jack enclosure. The case is designed for durability, portability, and daily carry, while remaining fully open-source and easy to reproduce.

All 3DP-related files are maintained in:

Step 0 — Gather Required Parts

| Item | Qty | Link |

|---|---|---|

| M2×0.4 Heat-Set Thread Insert (Ø 3 × H 2 mm) | 10 | Amazon |

| M2×0.4 Ultra-Low Head Torx Screw (3 mm) | 8 | Amazon |

| M2×0.4 Hex Socket Head Cap Screw (6 mm) | 2 | Amazon |

| Plastic Optic Fiber (Ø 1.2 – 1.5 mm) | 1 | Amazon |

Note

Screw lengths are important. Using longer screws may damage the PCB or deform the enclosure.

Step 1 — Print the Case

Supported materials:

- PLA+

- PETG (strongly recommended)

- ABS

Recommended Print Settings

PETG! PETG! PETG!

- Layer height: 0.16 – 0.20 mm

- Infill: 30 – 50 %

- Supports: Only where needed

- Orientation: Flat face down

Warning

Avoid resin / SLA printing. These materials are brittle and not suitable for heat-set inserts or daily mechanical stress.

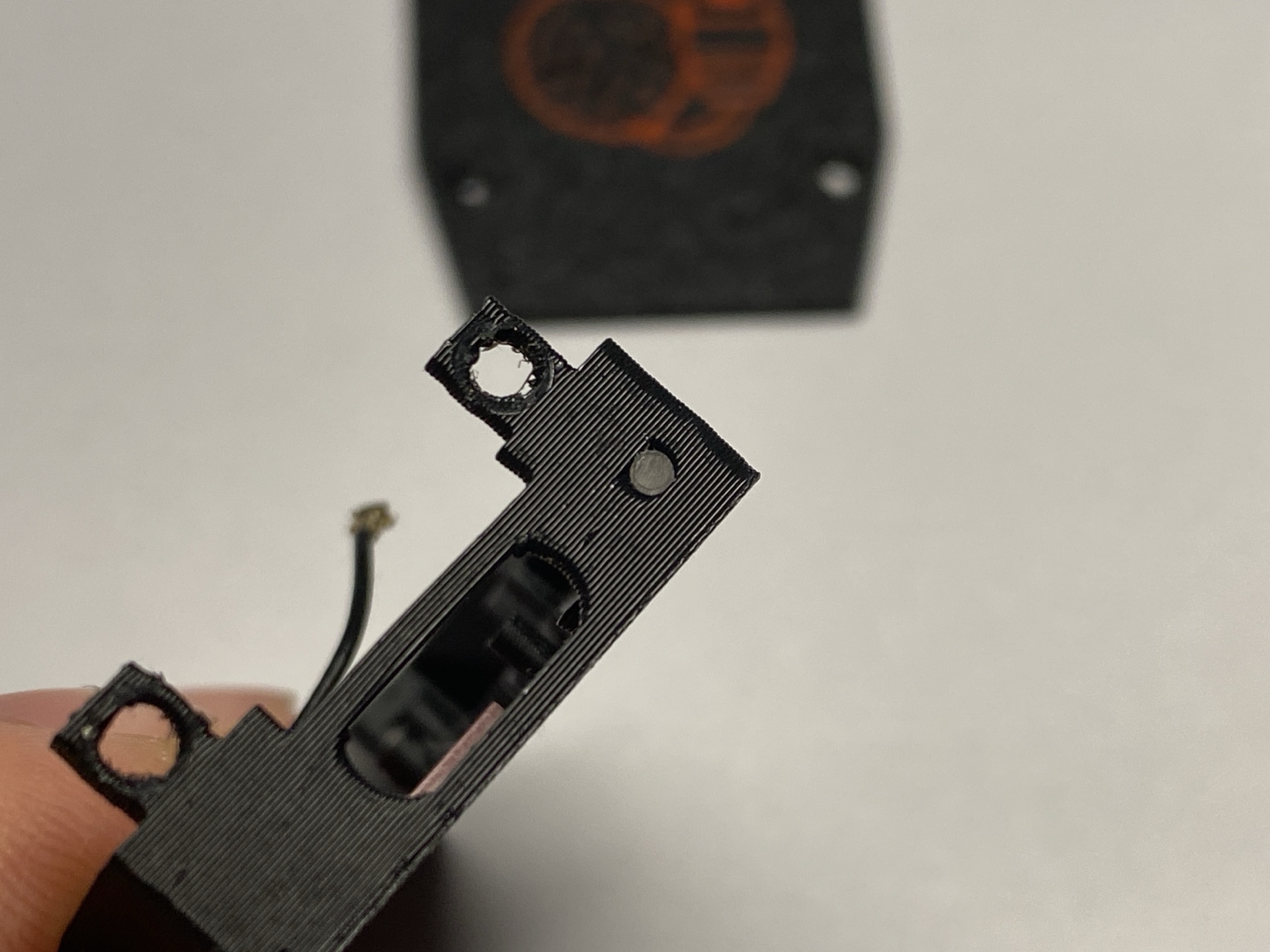

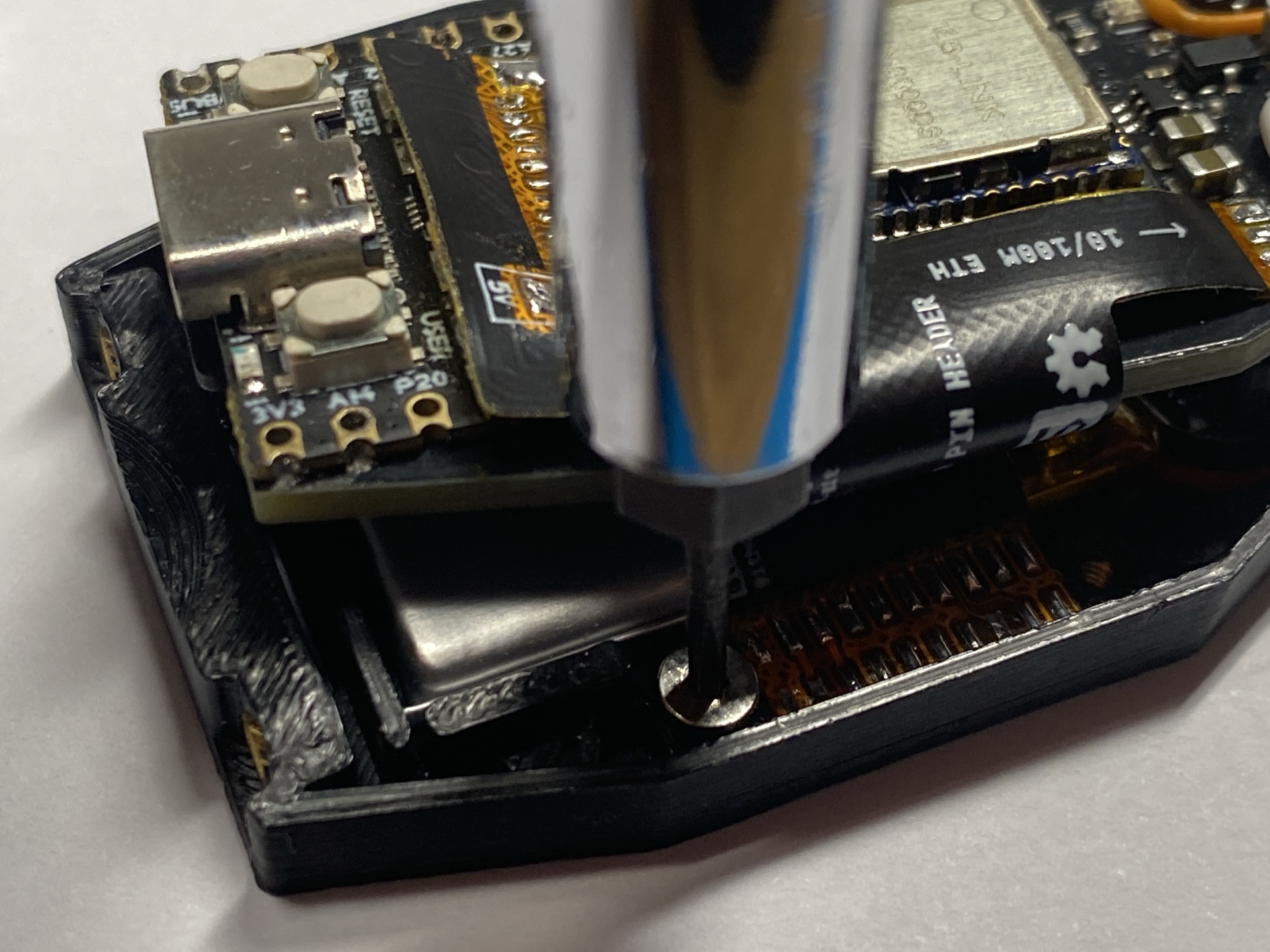

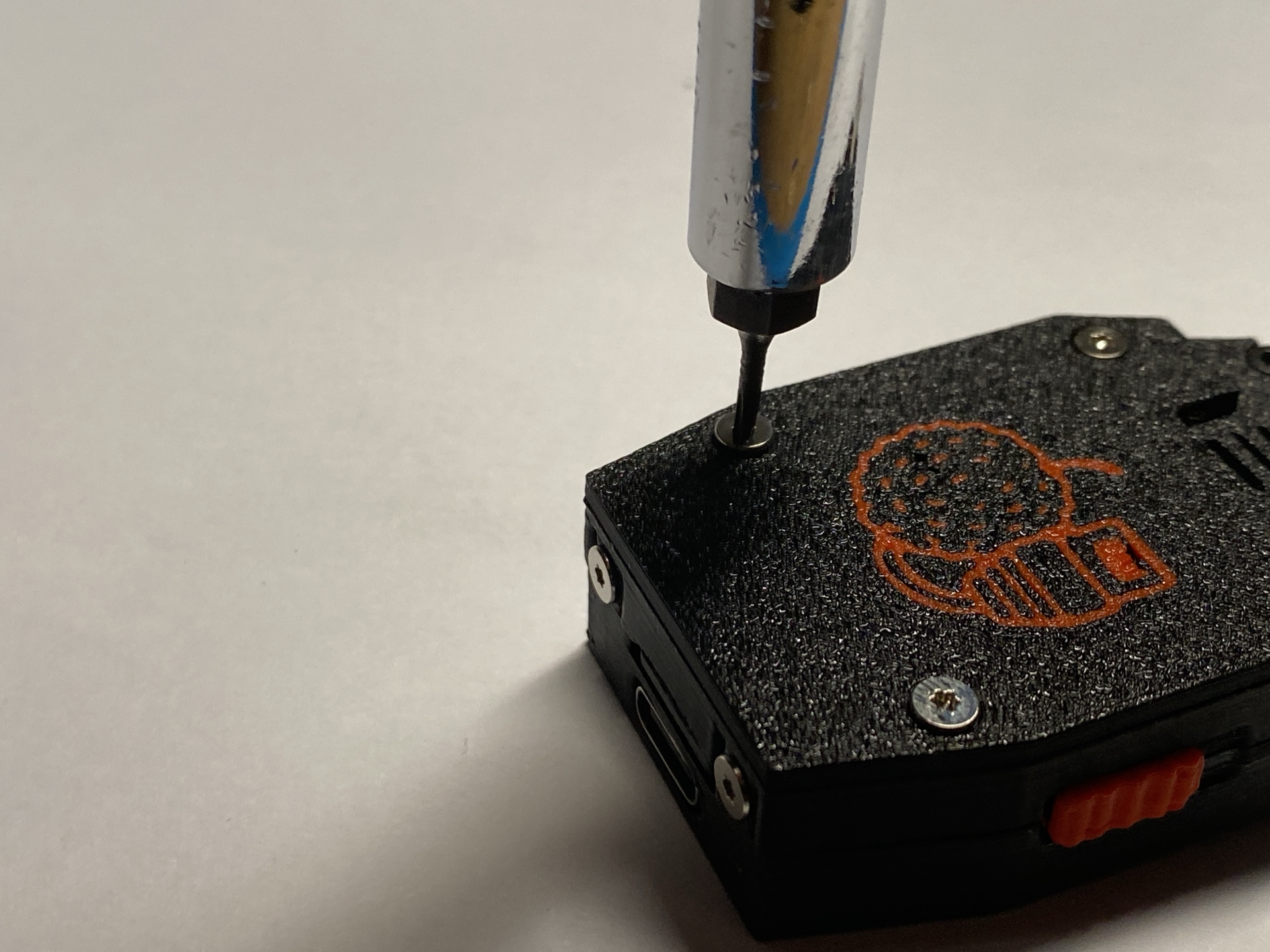

Step 2 — Install Heat-Set Inserts

- Heat your soldering iron to 180 – 200 °C.

- Align the heat-set insert with the hole.

- Press gently while heating until the insert sits flush.

- Allow the plastic to cool completely before installing screws.

Tip

If this is your first time using heat-set inserts, practice on scrap prints first.

Step 3 — Add Optical Fiber for LED Light Pipe

- Insert plastic optic fiber into the LED holes.

- This diffuses the internal LED into a clean external glow.

- Trim the fiber ends flush with the case surface.

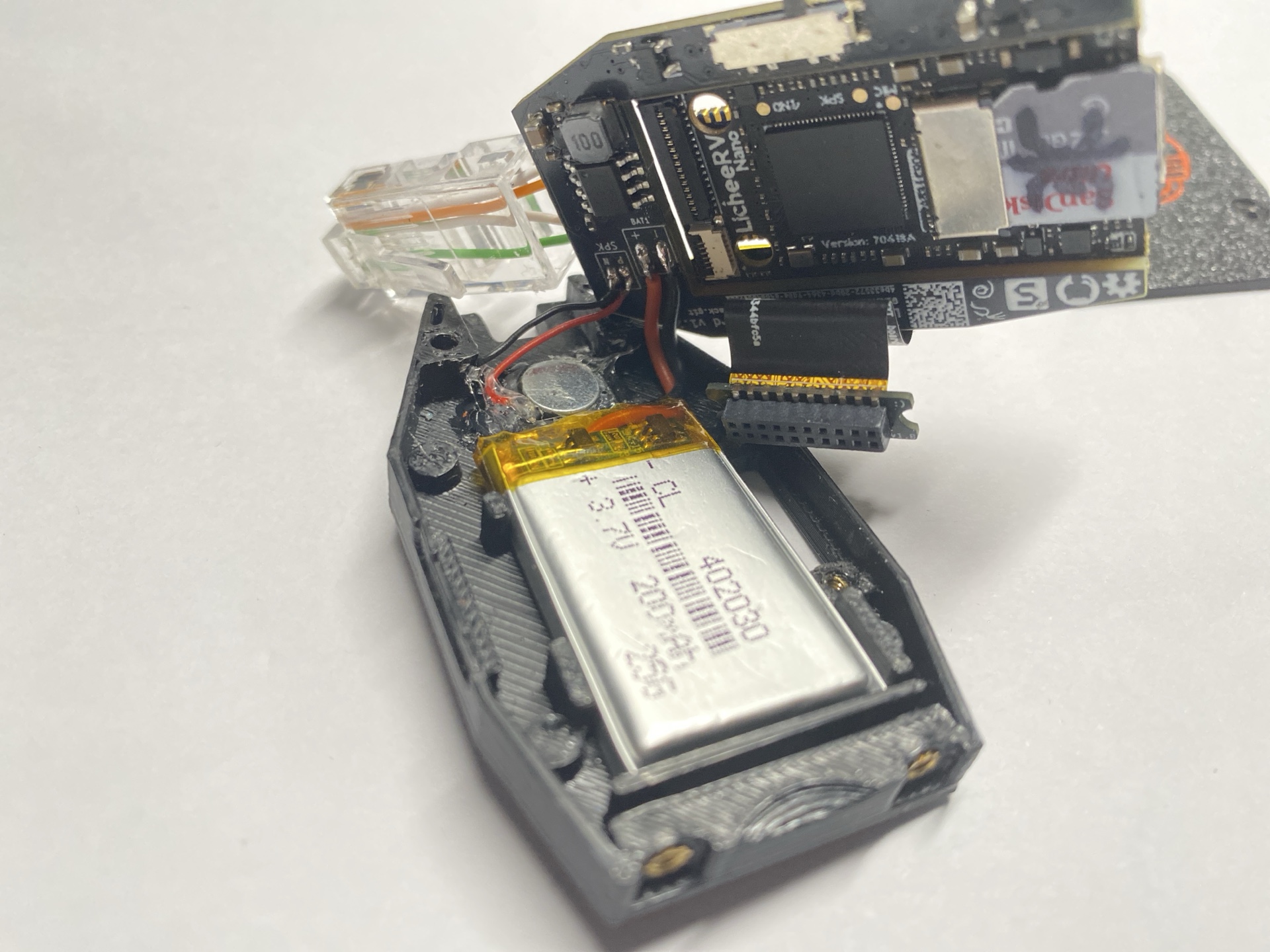

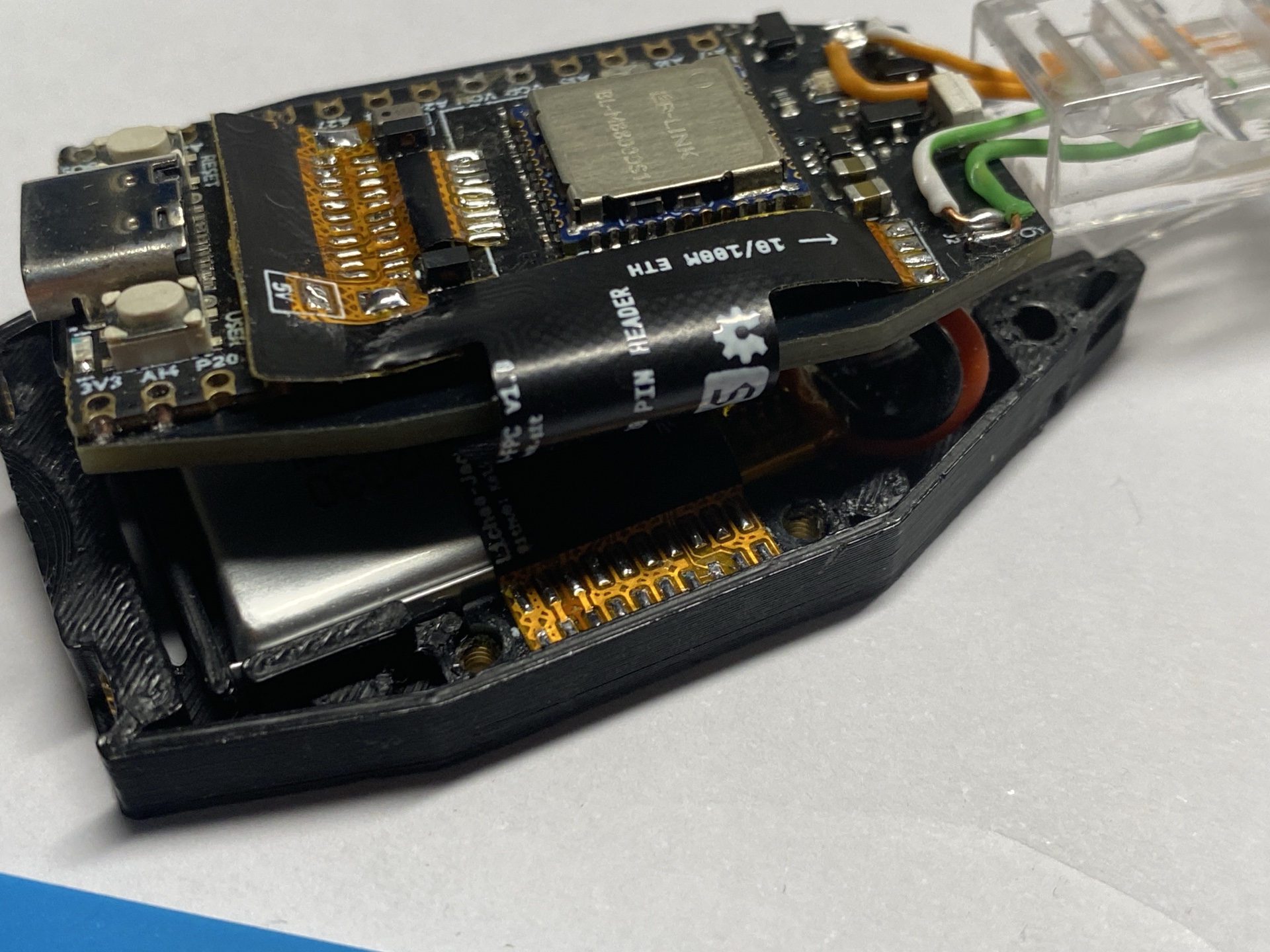

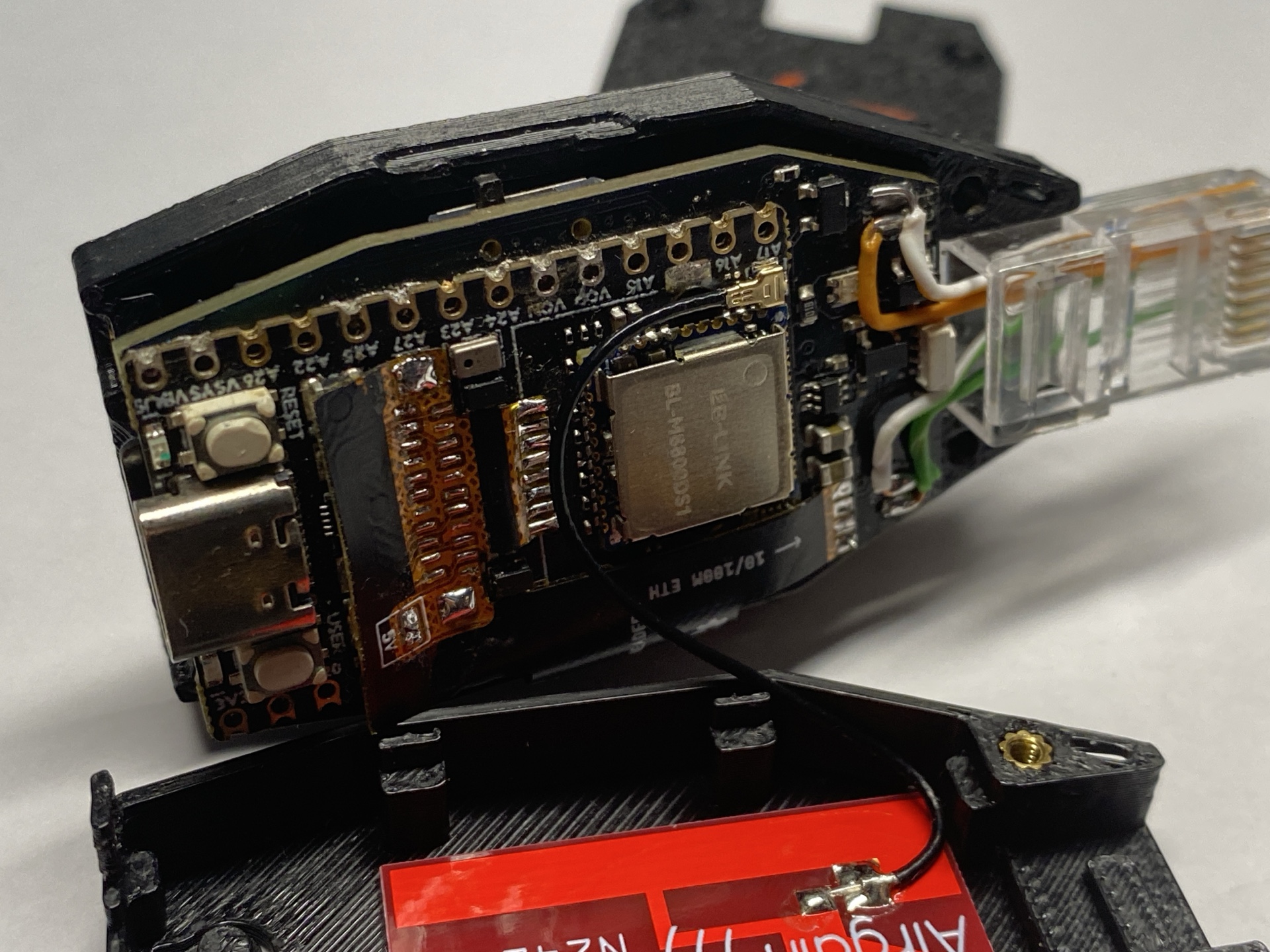

Step 4 — Final Assembly

- Place the PCB assembly into the bottom shell.

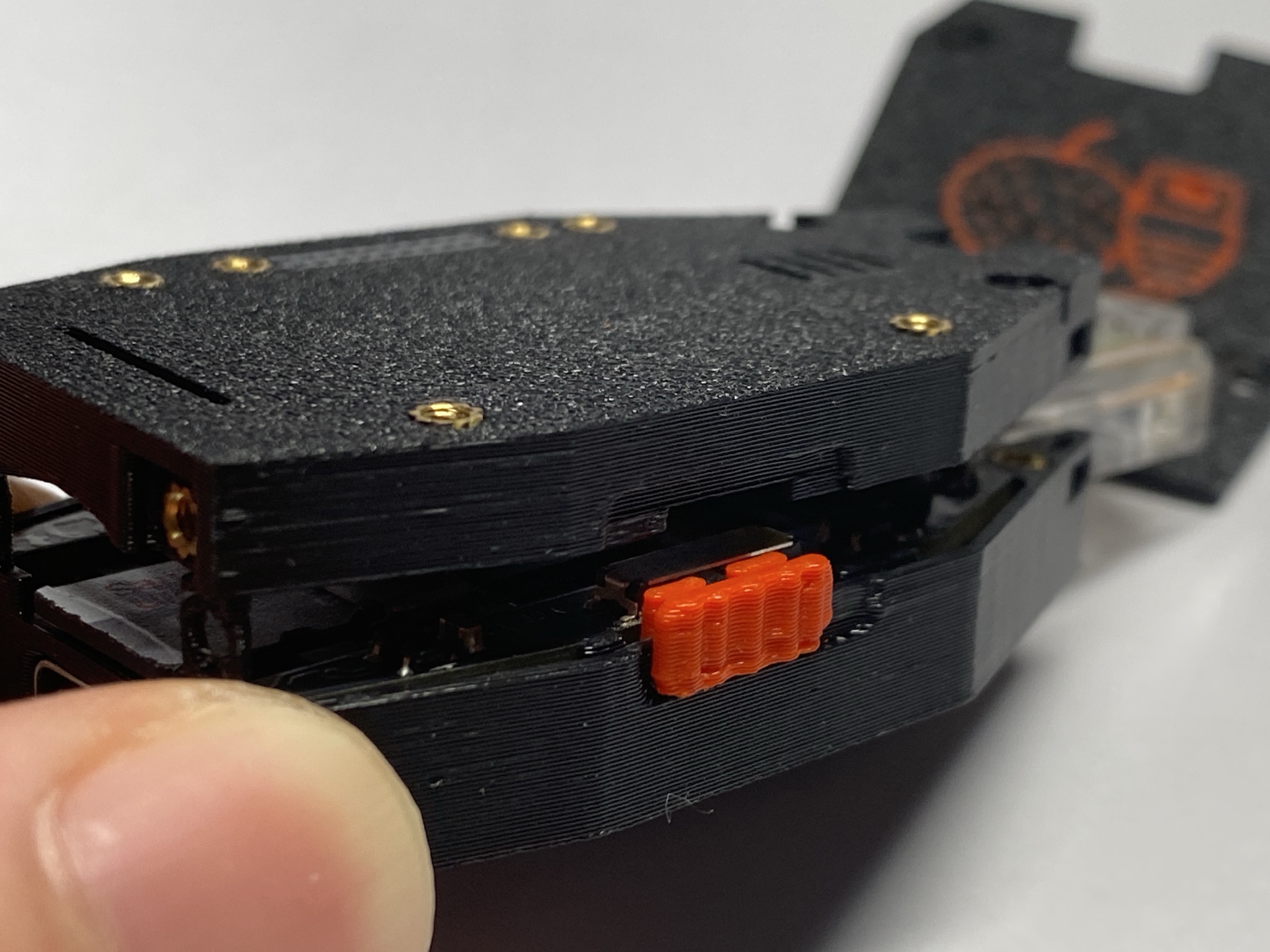

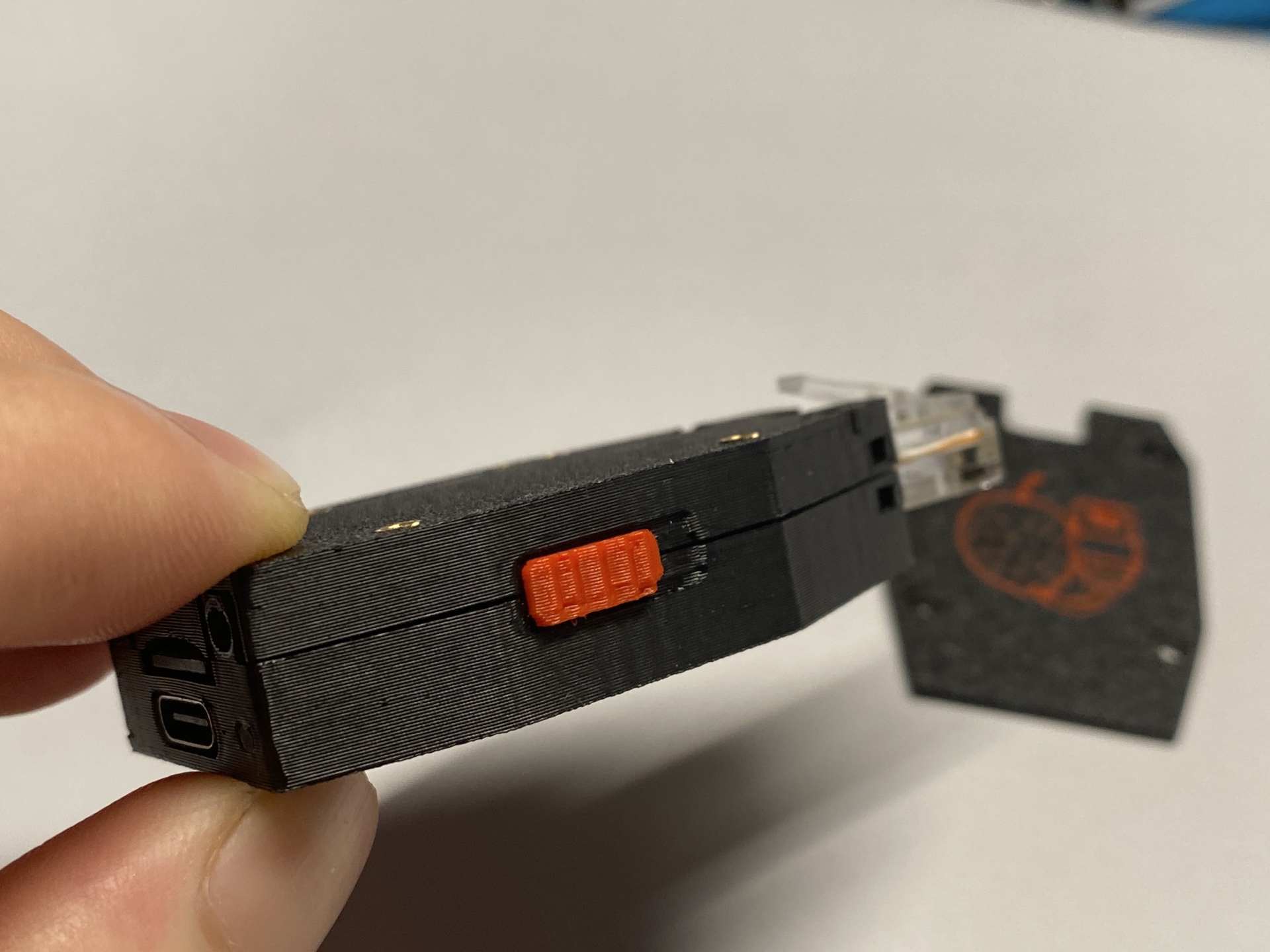

- Insert the switch header into the side slot before closing the case.

- Align the top shell.

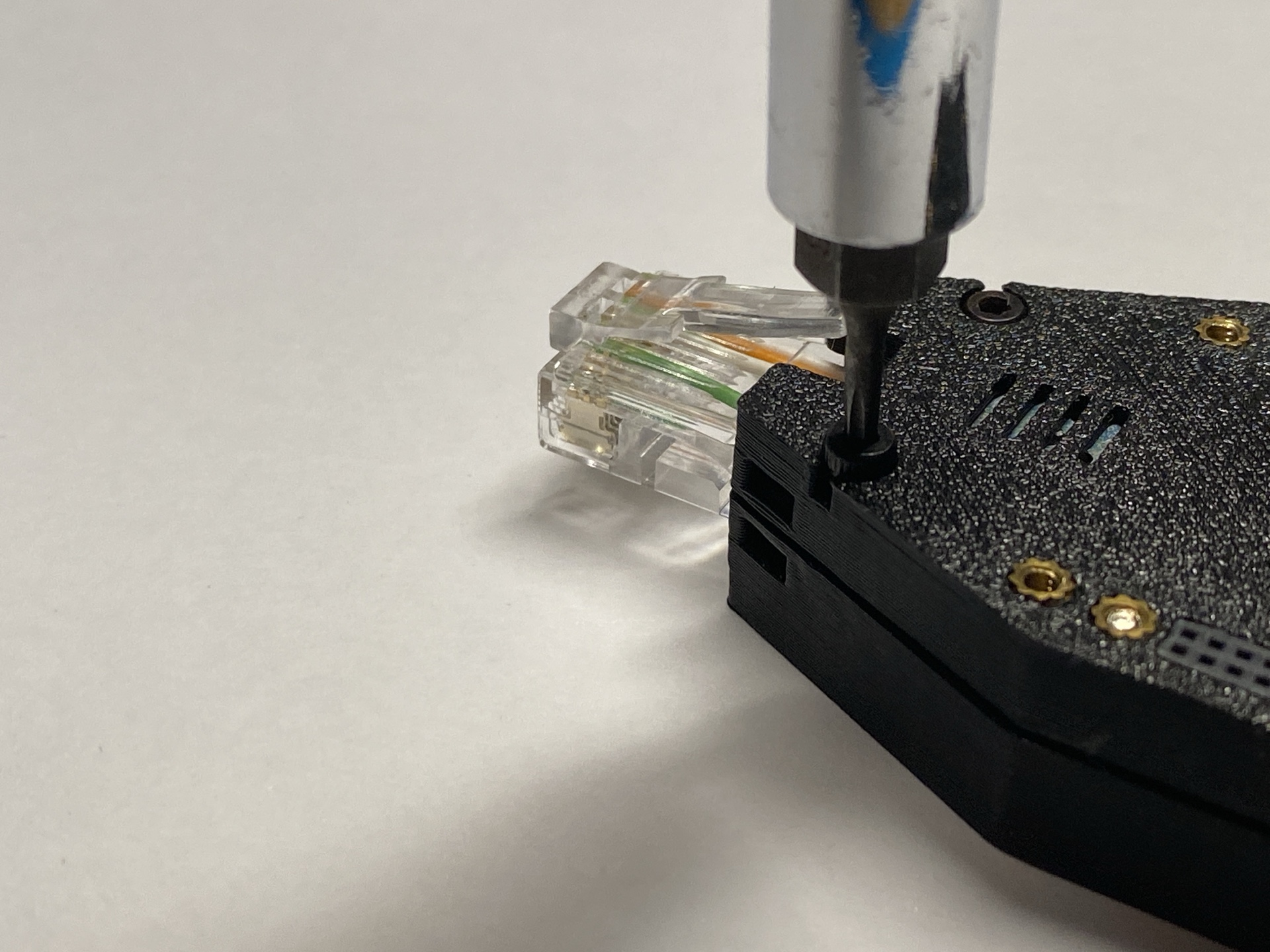

- Secure with M2 screws.

- Tighten gently — do not overtighten.

Optional Accessories

RJ45 Dummy Plug

- Acts as a dust cover for the Ethernet port

- Can also be used as a keychain anchor

Badge Plate (60 × 20 mm)

- Customizable badge area

- Add logos, callsigns, team names, or project labels

Extension Module Cover Plate

- Protective cover plate for the extension-module opening

- Prevents dust ingress when no EXT module is installed

- Improves structural rigidity and aesthetics

- Optional logo engraving supported

Design Notes

- The enclosure is optimized for daily carry and field use

- Heat-set inserts allow repeated opening without plastic wear

- Optical fiber provides visibility without external LEDs

Enjoy building your custom Lichee-Jack enclosure

If you modify or remix the case, consider sharing it back with the community!

Last updated on